In today’s competitive business environment, companies are constantly looking for efficient ways to reduce costs, improve product quality, and scale operations. One of the most effective strategies to achieve these goals is third-party manufacturing. This model is widely adopted across various industries, especially in pharmaceuticals, cosmetics, food, and supplements.

But what exactly is third-party manufacturing, and how does it work? This blog will break it down in simple terms.

What is Third-Party Manufacturing?

Third-party manufacturing, also known as contract manufacturing, is a business arrangement where a company outsources the production of its products to another company.

Simply put:

You own the product concept, brand, and marketing

Another company is responsible for manufacturing the product

This model allows you to focus on branding, distribution, and customer engagement while leaving the manufacturing process to experienced professionals.

How Does It Work?

The process of third-party manufacturing is relatively straightforward and involves the following steps:

Partner Selection – Choose a reliable third-party manufacturer.

Product Formulation – Share your formula or select from available options.

Packaging Design – Customize labels and packaging with your brand identity.

Production – Manufacturer produces the product in the desired quantity.

Delivery – Finished goods are shipped to your warehouse or distribution center.

Advantages of Third-Party Manufacturing

Third-party manufacturing offers several benefits, especially for startups and small to mid-sized businesses.

Cost Savings

No investment required for production facilities or equipment

Reduced labor and overhead costs

Focus on Core Business

You can focus on sales, marketing, and customer service

Frees up resources for business development

Access to Expertise

Manufacturing is handled by skilled professionals

Ensures compliance with industry standards and regulations

Faster Time to Market

Quick production and delivery cycles

Enables rapid product launches

Scalability

Easily scale production up or down based on demand

No need for additional infrastructure investment

Industries That Commonly Use Third-Party Manufacturing

This model is used in several industries, including:

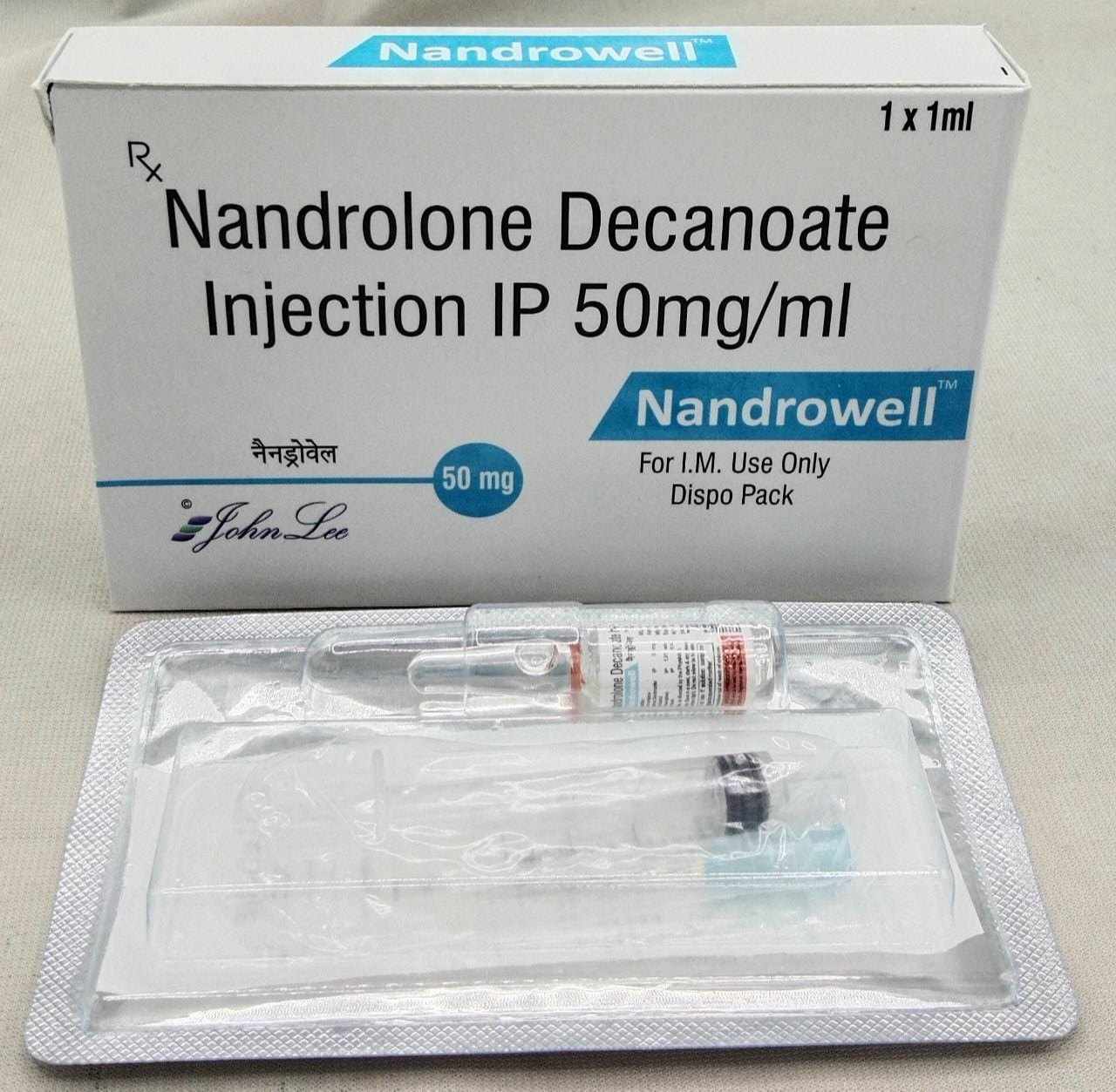

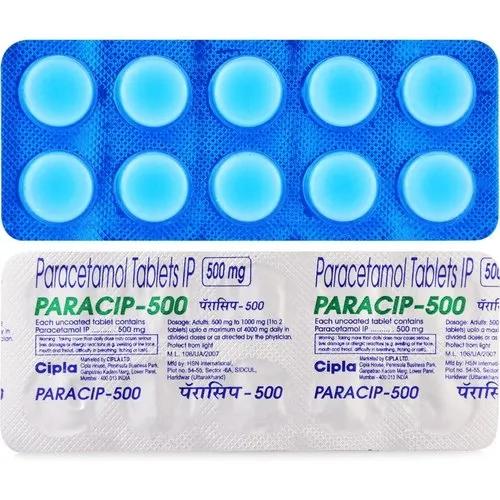

Pharmaceuticals – Tablets, capsules, syrups, ointments

Cosmetics and Skincare – Creams, lotions, soaps, hair care products

Food and Beverages – Snacks, juices, packaged foods

Nutraceuticals and Supplements – Protein powders, herbal capsules, vitamins

Household and Cleaning Products – Detergents, air fresheners, cleaners

Key Factors to Consider When Choosing a Manufacturer

Choosing the right third-party manufacturer is crucial for product success. Consider the following factors before signing a contract:

Certifications and Compliance

Look for certifications such as GMP, ISO, FDA, or equivalent

These ensure quality standards and regulatory compliance

Production Capacity

Ensure the manufacturer can meet your order volumes

Check their minimum order requirements and flexibility

Quality Assurance

A good manufacturer should have a dedicated quality control team

Ask for product samples, lab test reports, and quality checks

Transparency

Clear communication about timelines, materials, and pricing

Open disclosure avoids misunderstandings later

Reputation

Check online reviews and industry feedback

Ask for references and visit the manufacturing site if possible

Challenges of Third-Party Manufacturing

Despite its many advantages, third-party manufacturing also has its challenges:

Limited Control

Since production is outsourced, you have less control over the process

Quality or delivery delays can affect your brand reputation

Dependence on the Manufacturer

Any disruption in their supply chain can impact your operations

You may be dependent on a single vendor for your entire product line

Confidentiality Risks

Sharing product formulas or trade secrets can be risky

Requires strict legal agreements to protect intellectual property

Tips for Success in Third-Party Manufacturing

To make the most out of a third-party manufacturing arrangement, follow these best practices:

Build a strong relationship with your manufacturer based on trust and transparency

Clearly define all terms in the agreement including quality, quantity, cost, and timelines

Monitor quality regularly through audits and testing

Plan inventory ahead of time to prevent stockouts

Protect your brand through NDAs and intellectual property agreements

Is Third-Party Manufacturing Right for You?

Third-party manufacturing is an excellent solution for businesses looking to:

Launch a new product quickly

Reduce operational costs

Scale production without capital investment

Leverage the expertise of experienced manufacturers

Whether you’re a new brand entering the market or an established business looking to expand, third-party manufacturing can provide the flexibility and efficiency needed to grow faster and smarter.

Conclusion

Third-party manufacturing is not just a cost-saving strategy; it's a powerful tool for scaling a business while maintaining product quality and brand integrity. By choosing the right partner, setting clear expectations, and maintaining good communication, you can turn third-party manufacturing into a long-term competitive advantage.

If you're planning to launch a product and don’t want to deal with the complexities of manufacturing, third-party manufacturing might just be the perfect solution.

Write a comment ...